Custompac Display

Lettering

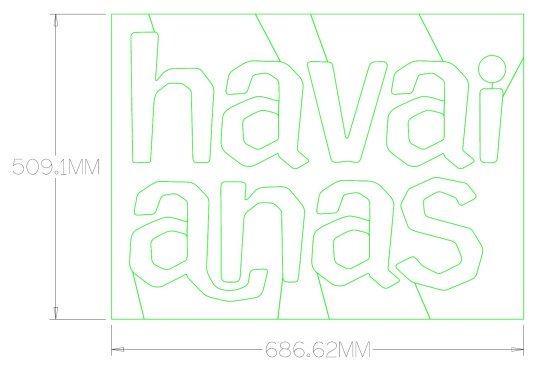

The profile cutting and waterjet technology we use to produce polystyrene and foam letters means that we can achieve any size and font.

Our design team use CAD software, to ensure items are to our client's exact specifications.

Props

Working from DXF, DWG, STP and PDF files (to name a few), our CAD software can import any client designs.

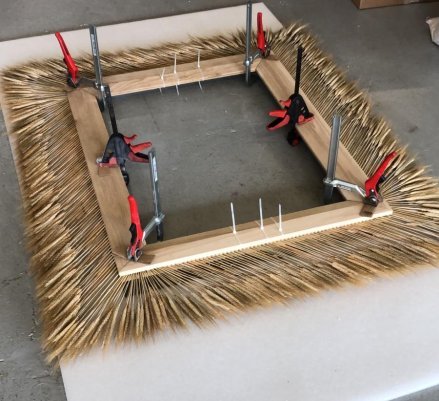

Our routers, knife cutters, waterjet machines and profile cutters then bring the projects to life...

Hard Coating

Require letters or props that may take a knock, or be exposed to the elements?

We offer a polyurethane hard coat, which gives the polystyrene added protection.

Spray Painting

Have a specific coloured logo in mind?

Send us a RAL reference and we can colour match.

Prop Production Processes

Our CAD operated, hotwired, profile cutter can cut both 2D and 3D polystyrene shapes.

Perfect for letters, logos, props, architecture , etc.

Display items produced from foam are cut on our CAD operated, waterjet machine.

The jet of pure water is quick, precise and dust free.

Our foam has the option of a SAB backing, for items that need to be bonded to displays.

Polystyrene, foam, and wood are among the materials that can be converted on our routing and knife cutting tables.

Our design team can import DXF, DWG, STP and PDF files (to name a few!)

If your props are going to be in busy areas, where they might get knocked... or spend time outdoors in the elements, we have a hard coating option.

The polyurethane hard coat is weatherproof and durable... and means props can be used countless times.

Working from the wide range of RAL colour references available means that we can spray lettering and props to whatever colour you're looking for.

Get In Touch

If you'd like to discuss a project with a member of our team, you can get in touch by...

Visiting: Our CONTACT page.

Calling: 01977 519339

Emailing: sales@custompac.co.uk